Innovation

There is no time like the future. Our constant search for alternative ways and new development of recycling methods sets us apart.

We want to live up to our zero waste philosophy to the greatest extent possible. If we come across an item that is deemed non-recyclable, we aim to develop suitable recycling methods to extract secondary raw materials.

But we can’t do it alone. With our partner network within the textile industry and beyond we work towards a future in which resources are no longer wasted and raw material extraction, production and recycling are sustainably and economically intertwined.

AUTOMATED MATERIAL RECOGNITION

AUTOMATED MATERIAL RECOGNITION

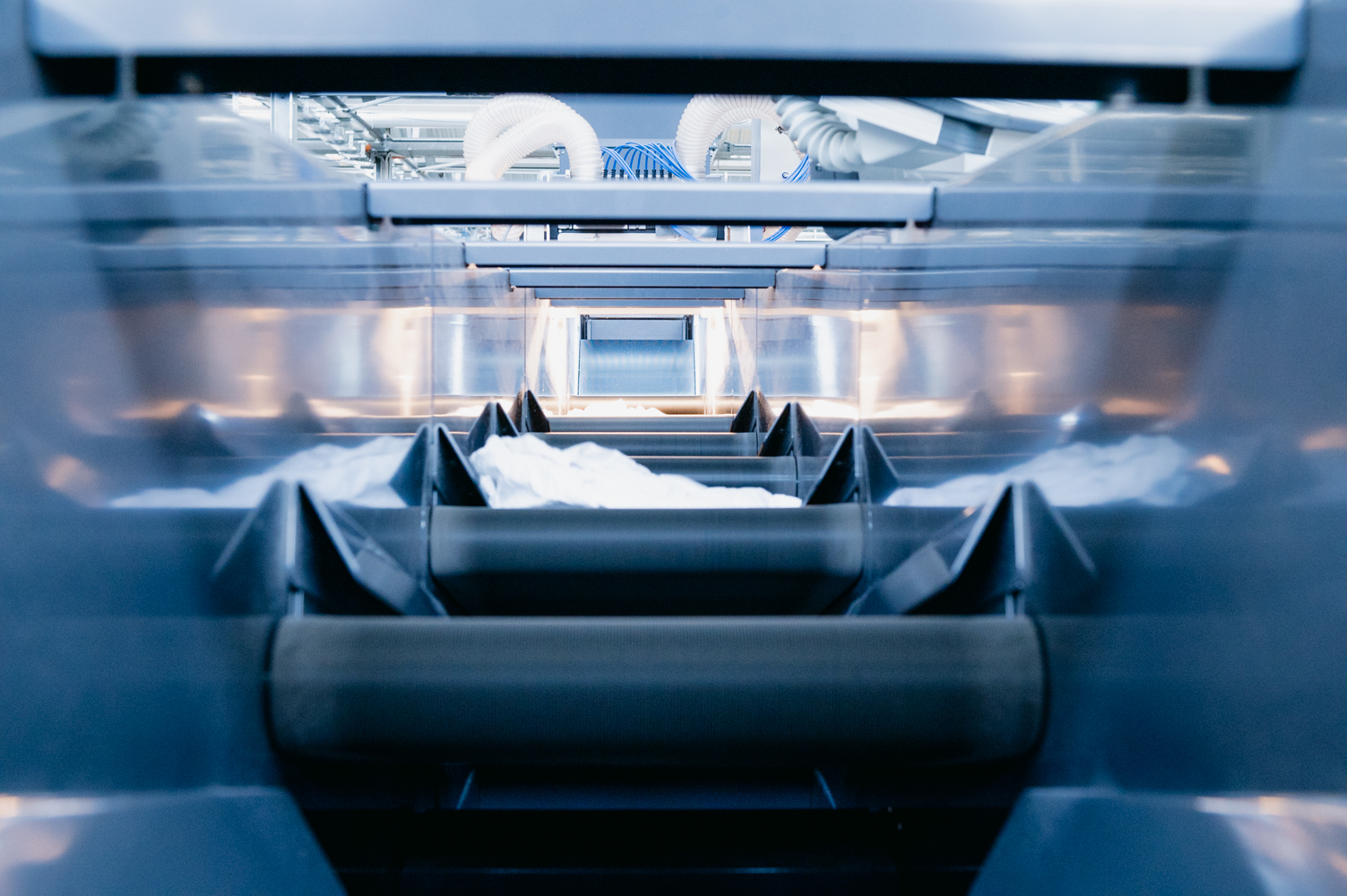

Our fully automated sorting for recycling set-up was born out of the SOEX led RESYNTEX project (2015-2019), a €9 million research endeavor supported by the EU aiming to chemically treat old textiles in order to convert them into secondary raw materials. Within the project, our goal was to implement a method to automatically separate second-hand clothes of the same material as a necessary step towards industrial chemical recycling. In May 2019, a pilot semi-automatic separator system for used textiles was installed in our SOEX plant in Wolfen, Germany. After two years of successful test runs and analysis, we were able to fully launch our automated and scalable sorting for recycling set-up in May 2022.

SHOE RECYCLING

SHOE RECYCLING

Every year more than 20 billion pairs of shoes are produced world wide. According to Recycling International, no more than 5% of them are collected and recycled once they have been worn out.

With our partners we therefore developed our first footwear recycling facility. The plant processes all types of footwear and separates them into various components. Some of these secondary raw materials extracted can then be reused in the manufacturing of other products.

Feel free to contact us if you have any questions about the use of individual secondary raw materials, would like to know the technical specifications or if you would like to request samples!